Introduction: Understanding the Situation

In today’s competitive landscape, manufacturing firms often struggle with high operational costs that negatively impact their profitability. Our client, a mid-sized manufacturing company, faced considerable challenges in managing production efficiency and resource allocation. The situation was dire: the firm needed a sustainable solution to streamline processes and minimize expenses.

The Task: Identifying Areas for Improvement

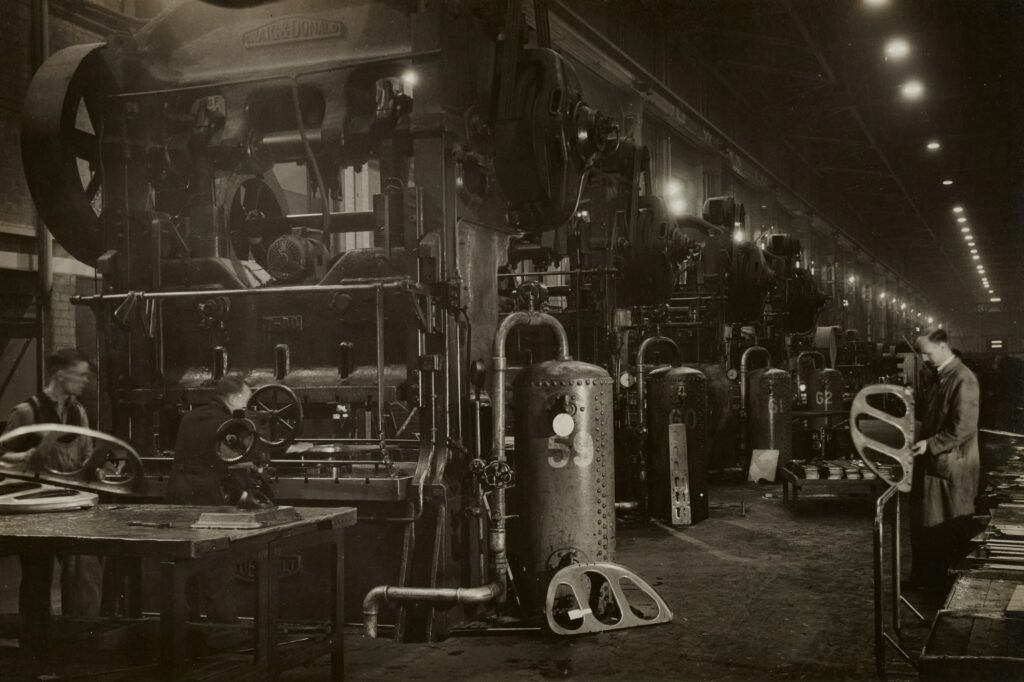

On engaging with the client, our primary task was to conduct a comprehensive assessment of their operational framework. This meant identifying key areas where inefficiencies existed. Our analysis revealed excessive labor costs, outdated machinery, and a lack of effective inventory management as critical factors contributing to the overall operational burden.

Action: Implementing Strategic Solutions

To address the identified issues, Dream Logicx employed a three-pronged approach. First, we recommended the adoption of automation technologies to enhance production workflows. Next, we facilitated training programs to upskill employees, ensuring adaptability to new processes. Finally, we introduced a robust supply chain management software that optimized inventory levels. By deploying these solutions concurrently, we aimed to create a cohesive strategy for operational cost reduction.

Result: Achieving Measurable Impact

The implementation of our strategies yielded impressive results within just six months. The manufacturing firm reported a staggering 20% reduction in operational costs, enhancing both profitability and sustainability. Additionally, employee morale improved as processes became more efficient, leading to higher productivity. This case illustrates that with the right analysis and tailored solutions, significant cost savings are possible in the manufacturing sector.